The cannabis industry’s growth is unparalleled, and with it, the need for efficient, precise cartridge filling solutions has become paramount. This guide dives deep into the capabilities, advantages, and limitations of four leading cartridge filling machines: CNC Packaging Inc’s C900X and C-SOLO, KISS Packaging Systems’ APD Series Fillers, CoolJarz’s HotShot™ Pro, and offerings from Detroit Dispensing Solutions. By understanding the intricacies of each option, cannabis business owners can make informed decisions tailored to their production needs.

CNC Packaging Inc: Elevating Precision and Efficiency

C900X Automated Cartridge Filling & Capping Machine

The C900X is a testament to CNC Packaging Inc’s commitment to innovation, designed to fill and cap up to 900 cartridges per hour. This model shines in its ability to manage high viscosity oils with a fully heated dispensing system, ensuring minimal product waste and maximum efficiency.

- Pros:

- Exceptional filling accuracy and consistency.

- Comprehensive system with both filling and capping capabilities.

- User-friendly interface for ease of operation.

- Cons:

- Base model is specific to flat tip screw on style cartridges.

- Requires air compressor.

C-SOLO Semi-Automatic Vape Cartridge Filling Machine

Tailored for versatility, the C-SOLO boasts a hands-free operation and the capacity to fill up to 1800 units per hour. It’s engineered to handle pods, disposables, carts, and luer lock syringes, making it a flexible option for various operations.

- Pros:

- 1800 per hour filling speeds

- Versatile across different cartridge types.

- Low maintenance enhances operational uptime.

- Cons:

- Manual operation elements may not be ideal for all setups.

- Requires separate air compressor.

KISS Packaging Systems: Adaptive Solutions for Liquid Diversity

APD Series Fillers

KISS’s APD Series stands out for its ability to handle a broad spectrum of liquid viscosities, from the thinnest to the most viscous. These machines are designed with advanced PLC controls and touch screen displays, enabling precise control and flexibility.

- Pros:

- Versatile for a wide range of viscosities and container sizes.

- High volume and speed capabilities enhance productivity.

- Advanced control for accurate fills, reducing overfills and product waste.

- Cons:

CoolJarz: HotShot™ Pro – Compact, Efficient, and Economical

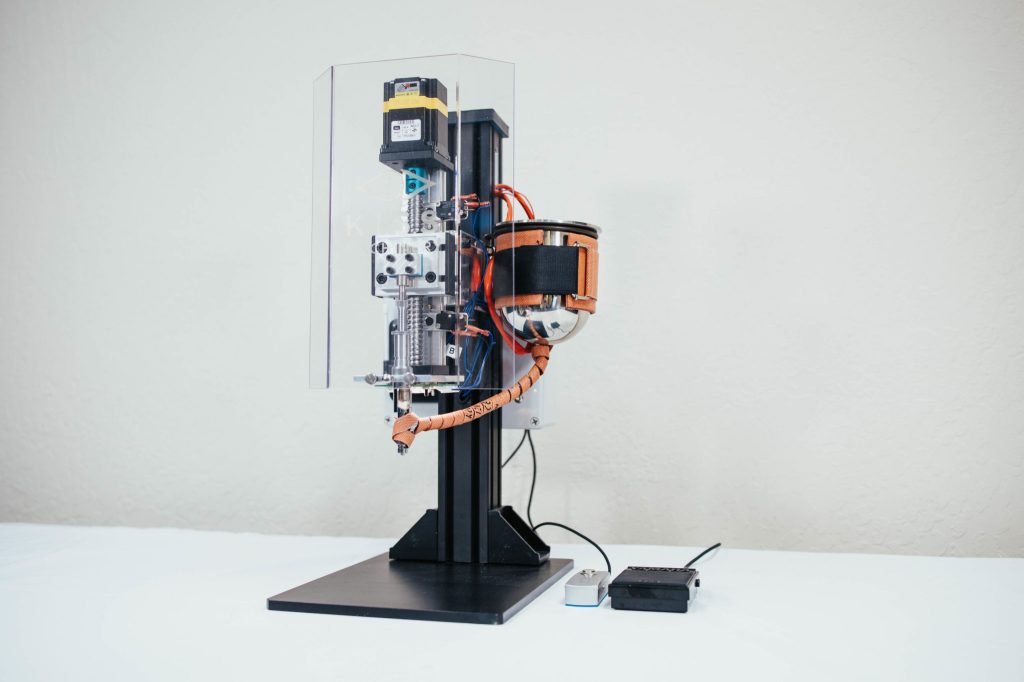

HotShot™ Pro Cartridge Filler

Designed for small to large-scale operations, the HotShot™ Pro by CoolJarz is a game-changer for businesses seeking efficiency and versatility without a large footprint. This machine combines the convenience of portability with the robust functionality required for precise and efficient cartridge filling.

- Pros:

- Economically priced, offering significant value.

- Compact design saves valuable workspace.

- Capable of handling a diverse range of oil viscosities.

- Cons:

- Semi-Automatic, requires operator at all times.

- No capping function.

Detroit Dispensing Solutions: Customized Filling Excellence

Detroit Dispensing Solutions is reputed for tailoring their technologies to fit specific industry needs, focusing on precision, adaptability, and efficiency. Although specific models and detailed descriptions were not directly provided, their solutions typically encompass:

- Pros:

- High customization to match unique product requirements.

- Precision dispensing for accurate, consistent fills.

- Potentially capable of high-speed operation for improved productivity.

- Cons:

- Custom solutions may come at a higher cost.

- Complexity could require specialized operation and maintenance expertise.

Choosing the Right Cartridge Filler

The decision on which cartridge filling machine to invest in hinges on several factors: the scale of your operation, the nature of the products you’re filling, budget constraints, and future scalability. Engaging directly with manufacturers for demos and consultations can provide insights beyond specifications, helping you to envision how each solution fits into your production ecosystem.